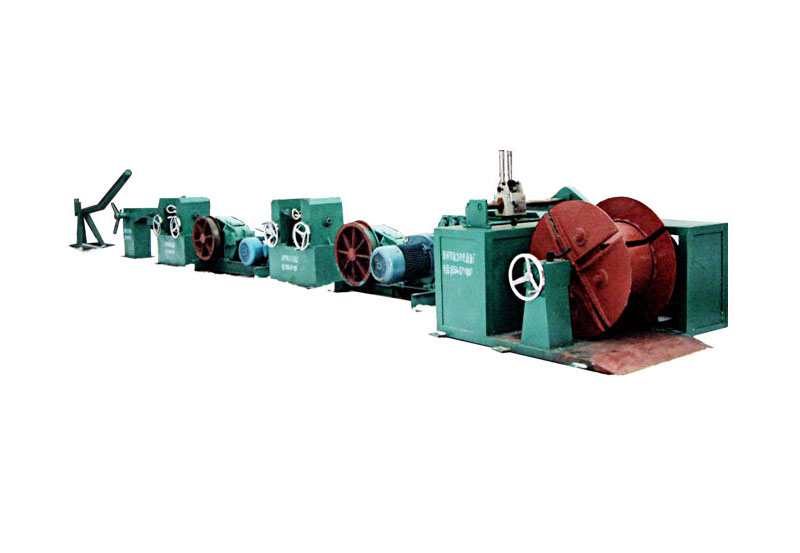

ZJ series of cold-rolled ribbed steel bar production line is 6.5 ~ Phi Phi 12 mm hot rolling round steel after cold rolling reduction after the surface of cold formed steel processing equipment three with crescent rib. Rolled ribbed steel products can meet the GB13788 - 2000 standard.

ZJ series cold rolling ribbed steel bar equipment production line will be 6.5 to Phi 12 mm hot-rolled 1, and can be equipped with an original drawing drum, without lubrication, no lubrication, cost savings, no dust production.

2, this series of cold rolling equipment can be alloy roller, table horizontal heavy wire drawing machine, easy to wear silk, simple adjustment. Not because of improper adjustment, resulting in broken wire, finished product quality instability and other ills.

3, the machine adopts steel wear-resistant cylinder, to solve the regular welding grinding drum troubles.

4, such as reducing the diameter of about 1 millimeters, you can use a wire drawing machine to operate more simple, more power saving.

5 and two mills are all steel structure, bearing capacity, will not damage.

6 、 the motor adopts AC asynchronous stepless speed regulation motor, the control circuit is simple, the reliability is high, the maintenance is almost free, the operation is simple, and it can also be equipped with frequency conversion speed regulation.

Note: ZJ series can only produce cold rolled ribbed steel bars. If finished products need straight bars, please choose ZT series products or other straightening machines.

|

Name

|

Company

|

Technical parameter

|

|

|

|

|

|

On-line straightening

|

On-line straightening

|

On-line straightening

|

On-line straightening

|

|

Model

|

|

ZJ8-7

|

ZJ12-10

|

ZJ8-7A

|

ZJ12-10A

|

ZT8-7A

|

ZT12-10A

|

ZT8-7B

|

ZT12-10B

|

|

Diameter of base metal

|

mm

|

φ6.5-8

|

φ6.5-12

|

φ6.5-8

|

φ6.5-12

|

|

|

φ6.5-8

|

φ6.5-12

|

|

mm

|

φ6.5-8

|

φ6.5-12

|

|

Finished size

|

|

φ5-7

|

φ5-10

|

φ5-7

|

φ5-10

|

φ5-7

|

φ5-10

|

φ5-7

|

φ5-10

|

|

Linear velocity

|

M / min

|

80

|

80

|

150

|

180

|

80

|

80

|

150

|

150

|

|

m/min

|

|

Predetermined length

|

m

|

|

|

|

|

1.5~90

|

1.5~90

|

1.5~90

|

|

m

|

|

Length of chute

|

m

|

|

|

|

|

8

|

8

|

8

|

8

|

|

m

|

|

Chute way

|

|

|

|

|

|

360°rotate

|

360°rotate

|

360°rotate

|

360°rotate

|

|

Two times the length of the collecting material

|

m/米

|

|

|

|

|

|

|

6▲

|

6▲

|

|

Two way of receiving material

|

|

|

|

|

|

|

|

360° rotate

▲

|

360° rotate

▲

|

|

Adjust speed

|

|

|

stepless

|

stepless

|

stepless

|

stepless

|

stepless

|

stepless

|

stepless

|

|

Length of finished conveyor belt

|

m

|

|

|

|

|

Additional as required

|

Additional as required

|

Additional as required

|

Additional as required

|

|

m

|

|

Cutting error

|

mm

|

|

|

|

|

±2.5

|

±2.5

|

±2.5

|

±2.5

|

|

mm

|

|

Total power

|

KW

|

~50

|

~65

|

~75

|

~110

|

~55

|

~75

|

~75

|

~110

|

|

KW

|

|

Total weight

|

kg

|

~5000

|

~6500

|

~6500

|

~9000

|

~7000

|

~8000

|

~8000

|

~11000

|

|

Kg

|

|

Working area

|

Length * width * height

|

20×2.5×2

|

20×3×2

|

25×3×2

|

25×3.5×2

|

32×4×2

|

32×4×2

|

40×4×2 Produce 12 meters

|

45×4×2 Produce 12 meters

|

|

Including line release, minimum

|

m

|

|

Stringing frame

|

|

|

|

Single group

|

two groups

|

Single group

|

Single group

|

two groups

|

two groups

|

|

Line regulator

|

|

|

|

yes

|

yes

|

|

|

yes

|

yes

|

|

Butt welder

|

|

|

|

yes

|

yes

|

|

|

yes

|

yes

|

|

Rolling times

|

|

2

|

2

|

2

|

2

|

2

|

2

|

2

|

2

|

|

Roll size

|

mm

|

φ150

|

φ150

|

φ150

|

φ150

|

φ150

|

φ150

|

φ150

|

φ150

|

|

Traverse method

|

|

Rod beam winding device

|

Rod beam winding device

|

Rod beam winding device

|

Rod beam winding device

|

|

|

|

|

|

Take-up weight

|

kg

|

700

|

1000

|

700

|

1000

|

|

|

|

|

|

Take-up

|

platform

|

1

|

1

|

1

|

1

|

|

|

|

|

|

On-line straightening machine

|

platform

|

|

|

|

|

1

|

1

|

1

|

1

|

|

Descaling machine

|

platform

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

|

Stress relief

|

platform

|

1

|

1

|

1

|

1

|

|

|

|

|

|

Operation console

|

platform

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

|

Cooling system

|

set

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

1

|

|

Wire drawing machine

|

|

500type

|

650type

|

650type

|

750type

|

650+750type

|

650+750type

|

650+800type

|

650+800type

|

|

The number of

|

|

2platform

|

2platform

|

2platform

|

2platform

|

2platform

|

2platform

|

2platform

|

2platform

|

|

rolling mill

|

|

2 Rolling Mills

|

2 Rolling Mills

|

2 Rolling Mills

|

2 Rolling Mills

|

2 Rolling Mills

|

2 Rolling Mills

|

2 Rolling Mills

|

2 Rolling Mills

|

|

Steel output by phi 7mm

|

kg

|

1449kg

|

1449kg

|

2718kg

|

3260kg

|

1449kg

|

1449kg

|

2718kg

|

2718kg

|

|

kg

|

Per hour

|

Per hour

|

Per hour

|

Per hour

|

Per hour

|

Per hour

|

Per hour

|

Per hour

|

|

Steel output by phi 10mm

|

|

|

2960kg

|

|

6660kg

|

|

2960kg

|

|

5550kg

|

|

|

|

Per hour

|

|

Per hour

|

|

Per hour

|

|

Per hour

|

|

Operator

|

People / Unit

|

2Above

|

2Above

|

2Above

|

2Above

|

3Above

|

3Above

|

3Above

|

3Above

|

|

Note:▲ the optional devices are subject to change without prior notice

|