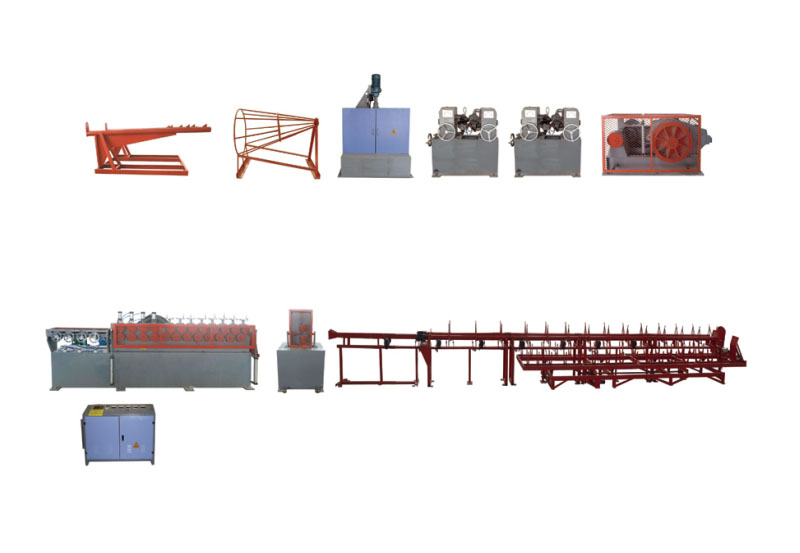

LZTZ12-10B series of cold-rolled ribbed steel bar production line can be reinforced by cold-rolled, hot rolled coil is formed on the surface of three sides of a crescent rib ribbed steel bars, cold rolled, straightening, cutting and blanking, machining engineering cast or prefabricated direct use of ribbed bar. Products meet GB13788-2000 standards. The machine is highly automated and easy to operate. It is an efficient on-line straightening production line (one time straight strip forming).

Technical parameters of cold rolled ribbed steel production line on three sides:

|

Model

|

Company

|

LZTZ12-10B (finished straightening)

|

|

Base metal (raw material)

|

mm

|

Φ6-12

|

|

Finished size

|

mm

|

Φ5-11

|

|

Linear velocity

|

m/min

|

180

|

|

Predetermined length

|

m

|

0.5~99

|

|

Length of chute

|

m

|

6~12 (more than 9 meters for optional)

|

|

Chute way

|

m

|

360°rotate

|

|

Two collect with sizes

|

m

|

9~12 (more than 9 meters for optional)

|

|

Adjust speed

|

|

frequency conversion

|

|

control mode

|

|

PLC+ touch screen

|

|

Cutting error

|

mm

|

±3

|

|

Total power

|

Kw

|

180

|

|

Total weight

|

Kg

|

~11000

|

|

The working area includes a small footprint

|

Length * width * height

|

50×4×2

|

|

Stringing frame

|

platform

|

There are two sets of guns

|

|

Line regulator

|

platform

|

yes

|

|

Rolling times

|

|

2

|

|

Roll size

|

|

Φ150

|

|

On-line straightening machine

|

platform

|

1

|

|

Descaling machine

|

platform

|

1 Electric pressure dedusting type

|

|

Operation console

|

platform

|

1

|

|

Cooling system

|

platform

|

1

|

|

Wire drawing machine (patent technology)

|

platform

|

Type 850 (no lubrication powder, environmental friendly type)

|

|

rolling mill

|

platform

|

2 Rolling Mills

|

|

Operator

|

People

|

3

|